Iqembu le-Kyocerayasungulwa ngo-1959 nguKazuo Inamori, omunye "wabaNgcwele Abane Bebhizinisi" eJapane. Ekuqaleni kokusungulwa kwayo, yayihileleke kakhulu emikhiqizweni yobumba kanye nemikhiqizo yobuchwepheshe obuphezulu. Ngo-2002, ngemva kokukhula okuqhubekayo, iKyocera Group yaba enye yezinkampani zeFortune 500, enezindawo zebhizinisi zomhlaba wonke ezihlanganisa izinto zokusetshenziswa, izingxenye, imishini, imishini, kanye nezinsizakalo, amanethiwekhi, kanye neminye imikhakha. Ngo-2019, iKyocera Group ihlela ukwakha ifektri yamabhethri e-Osaka, entshonalanga yeJapane, ihloseimakethe yokugcina amandla elanga.

Kuyaqondakala ukuthi iKyocera Group inamathemba aphezulu ngalo msebenzi futhi ihlela ukusekela ukuthuthukiswa kwebhizinisi lebhethri lokugcina amandla laseKyocera eminyakeni emi-5 ezayo ngemuva kokuqedwa kwephrojekthi. I-ROBOTECH yaklama futhi yakha uhlelo lokugcina impahla oluzenzakalelayo lwayo, yafeza ukuzenzekela, ukwenziwa kwedijithali, kanye nokuphathwa okuhlakaniphile kwenqubo yonke yokukhiqiza nokugcina, isiza ekuxazululeni amaphuzu abuhlungu njengezindleko eziphakeme, ukusebenza kahle okuphansi, izinqubo eziningi, kanye nokuphathwa kwezinto eziyinkimbinkimbi, ukunciphisa izindleko nokwandisa ukusebenza kahle, kanye nokufeza ukuxhumana okusebenzayo kanye nokusebenzisana phakathi kwemigqa yokukhiqiza nemishini.

Ukuze kuthuthukiswe izinga lokusetshenziswa kwesikhala sefektri yamabhethri, i-ROBOTECH isebenzise ngokugcwele okungaphezu kwalokhoIsikhala esime mpo esingu-4mfuthi wadala indawo yokugcina izinto ezenzakalelayo enezindawo ezimbili zokugcina izinto:indawo yokushaja nokukhipha ibhethrifuthiindawo yokuguga kwegumbi lebhethri lokushisangokusekelwe ezicini zekhwalithi yomkhiqizo, okuhlanganisa amasethi amabili ezinhlelo ze-stacker crane.

- Indawo yokushaja nokukhipha ishaja

- Isethi yesistimu ye-stacker crane

- Izikhala zempahla ezingu-5000

1. Indawo yokushaja nokukhipha ishaja

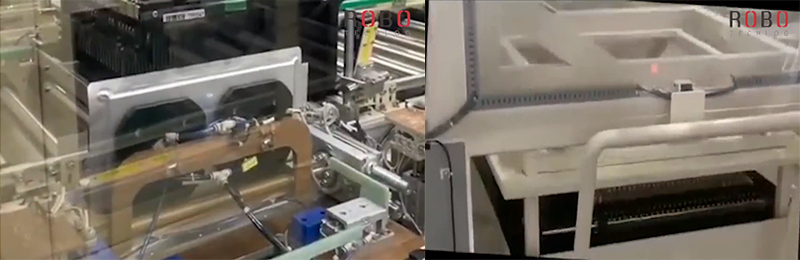

Isethi yeisitakii-craneuhlelokuhlelwe ekuhleleni kokushaja nokukhipha amandla esifundeni ukuze kufezwe isitoreji esiphephile nesingasebenzisi ugesi kakhulu ezindaweni ezingaphezu kuka-Izikhala zemithwalo ezingu-5000Ngenxa yezidingo zokuphepha eziphezulu zalo msebenzi, i-ROBOTECHuhlelo lwe-crane ye-stackerifakwe izithombe ze-infrared thermal kanye namadivayisi okuqapha, angathola ukukhubazeka ngesikhathi esifanele futhi aqinisekise ukusebenza okuphephile kwenqubo yonke. Futhi isignali ixhumene nedivayisi ngayinye yokushaja nokukhipha ngedivayisi yokudlulisa i-optical (8bit). Lapho i-stacker crane yenza umsebenzi "wokukhulula" noma "wokufaka ifoloko", isicelo somsebenzi sithunyelwa ngokuxhumana kwe-optical endaweni efanele yedivayisi yokushaja. Isinyathelo singathathwa kuphela ngemuva kokuthi isignali ye-OK yedivayisi yokushaja ivunyiwe.

-Indawo evamile yokuguga kwezinga lokushisa

- Isethi eyodwa ye-stackeri-craneuhlelo

-Izindawo zokugcina izinto ezingu-400

- Mumthwalo ophelele we-100KG

2. Indawo evamile yokuguga kwezinga lokushisa

Isethi eyodwa ye-stackeri-craneuhlelokuhlelwe ukuthiukuguga kwezinga lokushisa elijwayelekile ukuhlela kwesifunda, kufaka phakathi okungaphezu kwalokhoIzindawo zokugcina izinto ezingu-400, esetshenziswa kakhulu ukugcina amabhethri okwesikhashana enkambisweni evamile yokuguga kwezinga lokushisa, ngeumthwalo omkhulu we-100KG.

Ngenxa yokuzwela okukhulu kwezinto zebhethri ezintweni ezifana nomthofu, i-zinc, nethusi, ukuze kugwenywe izinto zangaphandle zensimbi kanye nothuli okuthinta ukuzinza komkhiqizo, i-ROBOTECHngokwezifiso ezengeziweiphrojekthi isekelwe ekukhetheni imishini ye-stacker crane. Idivayisi yokuhamba isebenzisa amasondo ambozwe ngerabha, izingxenye zensimbi zithola ukwelashwa kokufutha nge-electrostatic, kanti izingxenye ze-aluminium zithola ukwelashwa kwe-anodizing ukunciphisa ukukhiqizwa kwezinto zangaphandle zensimbi. Futhi izicisha-mlilo namadivayisi ezikhali afakiwe kwi-stacker crane ukuze kuhlangatshezwane nezidingo zefektri zokumelana nokushisa okuphezulu, ukungabi nothuli, ukuvimbela umlilo nokuqhuma.

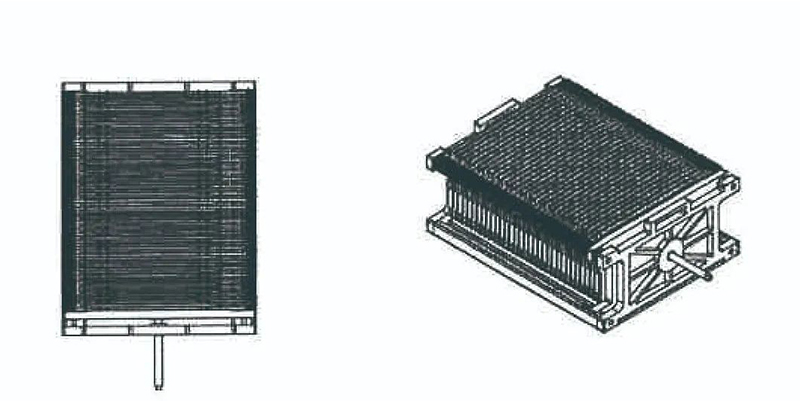

Kuhle ukusho ukuthi enqubweni yokukhiqiza amabhethri, ukuze kwenziwe ukusebenza kwawo kube okuzinzile,zidinga ukufakwa kudivayisi enomsebenzi wokucindezela ukuze kuphumule izinga lokushisa legumbi ngemva kokwakheka nokufakwa ekuphumuleni kwezinga lokushisa eliphezuluNgakho-ke, i-ROBOTECH isebenzisa ngqoamathreyi okucindezela ibhethrinjengezithwali zokugcina isitoreji. Lolu hlobo lwethreyi yokucindezela ibhethri lunezinzuzo ubuchwepheshe obukhona obungenazo, njengesakhiwo esilula, ukusetshenziswa okulula, ukusebenza kahle kokukhiqiza okuphezulu, ukusetshenziswa kwesikhala esincane, izindleko eziphansi zokusetshenziswa, kanye nokusetshenziswa okulula kokukhiqiza okuzenzakalelayo.indawo yokugcina yokushaja nokukhipha ishaja, lungisa ithreyi yokucindezela ibe yi-isimo esicindezelweKu-indawo yokugcina ukuguga kwegumbi lokushisa, lungisa ithreyi yokucindezela ibeisimo esixegayo.

Umdwebo wencazelo yethreyi: L865 * W540 * H290mm (isimo esikhululekile)

Umdwebo wencazelo yethreyi: L737 * W540 * H290mm (isimo esicindezelwe)

Umdwebo wencazelo yethreyi: L737 * W540 * H290mm (isimo esicindezelwe)

Ukuqedwa kwale phrojekthi kuhlangabezana nezidingo zesevisi yezokuthutha ezisebenzayo, eziphephile nezithembekile zeKyocera Group emkhakheni webhizinisi lebhethri lokugcina amandla. Ngokusekelwa kohlelo lokugcina impahla oluhlakaniphile lwe-ROBOTECH, kungaqinisekisa kakhulu izinga lokukhiqiza lokugcina amabhethri. Kwasheshisa ukuzenzekela, ubuhlakani, kanye nentuthuko eqhubekayo yeKyocera Group emakethe entsha yamandla.

I-NanJing Inform Storage Equipment (Group) Co.,Ltd

Ucingo oluphathwayo: +8625 52726370

Ikheli: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Iwebhusayithi:www.informrack.com

I-imeyili:[i-imeyili ivikelwe]

Isikhathi sokuthunyelwe: Ephreli-21-2023