Ama-semiconductor chips ayinsika eyinhloko yobuchwepheshe bolwazi kanye nobuchwepheshe obusafufusa obubalulekile kanye nemboni amazwe ancintisana ukuyithuthukisa.I-Wafer, njengezinto eziyisisekelo zokukhiqiza ama-semiconductor chips, idlala indima ebaluleke kakhulu ekuthuthukisweni kwemboni ye-semiconductor yaseShayina. Ngokuphathelene nomthamo wokukhiqiza ama-wafer, iShayina isivele ihola emhlabeni, kodwa njengoba "ukuntuleka kwama-chip" emhlabeni wonke kukhula, kuzosheshisa ukwanda kwamandla.

1. Isizinda Sephrojekthi

I-subsidiary yeqembu elibhalwe ohlwini lwemboni ye-semiconductor yasekhaya, njengomdlali ohamba phambili embonini kazwelonke yezinto zolwazi lwe-elekthronikhi, izibophezele ocwaningweni nasekuthuthukisweni, ekukhiqizweni kwezinto ze-semiconductor, izinto ezikhethekile ze-elekthronikhi, amadivayisi e-semiconductor kanye nobunye ubuchwepheshe. Umkhiqizo oyinhloko yi-semiconductor zone melting single crystal silicon wafer, enamandla amathathu aphezulu emhlabeni wonke kanye nesabelo semakethe yasekhaya se-ngaphezu kuka-80%.

Ukuze kusheshiswe ukwanda kwamandla, inkampani itshale imali ecishe ibe yizigidigidi ezintathu zamaRandi ukuqala ukwakhiwa kwephrojekthi enkulu yokukhiqiza nokukhiqiza i-silicon wafer yobubanzi bezifunda ezihlanganisiwe eYixing City, eSifundazweni saseJiangsu. Isigaba sesibili sale phrojekthi saqalwa ngo-2021, sinamathela emcabangweni othuthukisiwe we-"Industry 4.0" futhi sihlela ukusebenzisa ukukhiqiza okuhlakaniphile kulo lonke ulayini ukuze kufezwe ukuzenzekela, ukwaziswa, kanye nokwakhiwa okuhlakaniphile kwe-workshop. Ngemva kokuqedwa, umthamo wokukhiqiza ophelele uzoba ama-wafer epitaxial angu-220000 angu-8-intshi, ama-wafer acwebezelwe angu-200000 angu-12-intshi, kanye nama-wafer epitaxial angu-150000 angu-12-intshi ngenyanga, abe isisekelo sokukhiqiza i-silicon wafer enezinzuzo zomhlaba wonke. Ngakho-ke, ngokwendawo yokugcina impahla ehlakaniphile yeqembu,I-ROBOTECH ithuthukise izinga lobuhlakani, ulwazi, kanye nokwenza izinto ngokuzenzakalela kwesisekelo sayo sokukhiqiza ngokusebenzisa izinhlelo zokugcina izinto ezihlakaniphile ezithuthukisiwe.

2. Iphrojekthipukucheba

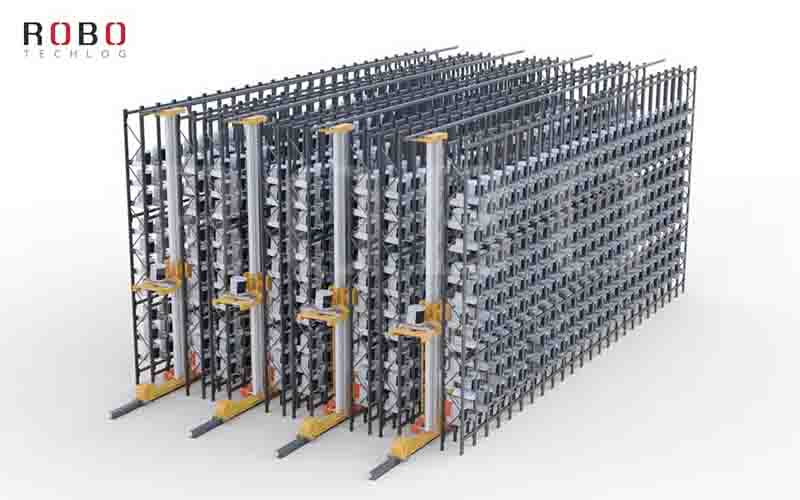

I-ROBOTECH isisebenzise ngokugcwele isikhala esiqondile esingamamitha ayi-6 sesisekelo sayo sokukhiqiza futhi ihleleIndlu yokugcina izinto ezenzakalelayo yohlobo lwebhokisi olunemizila emineukuthola imikhiqizo ye-semiconductor wafer, engathwala inani elingaphezu kwe-Izindawo zokugcina izinto ezingu-2000, ukwandisa ngempumelelo amandla okugcina ama-waferNgenxa yokuthi i-wafer isesimweni seshidi, isithwali sayo sisebenzisa isitsha sepulasitiki esibonakalayo esingu-330 * 330 * 300 esenziwe ngokwezifiso ukuze kube lula ukufinyelela i-wafer, enomthwalo omkhulu ongu-50kg.Kuxazululwe inkinga yezinqubo zokugcina i-wafer eziyinkimbinkimbi kanye nokusetshenziswa okulinganiselwe kwesikhala ezindaweni zokugcina impahla zendabuko, kwatholakala ukuthuthuka okubili ekusetshenzisweni nasekusebenzeni kahle kwesikhala.

• Uhlelo lwe-Zebra series stacker crane

• Isigqi sokukhiqiza esingu-100m/min kanye namahora angu-24 kanye no-63P/h ngomjikelezo ngamunye

Ngokuphathelene nokusebenza kahle, i-ROBOTECH ikhethai-zebra series stackeri-craneuhleloukugeleza kwezinto eziguquguqukayo okuphezulu, ngesivinini esivundlile se100m/min, okuhlangabezana ne-Isigqi sokukhiqiza samahora angama-24kwesisekelo sokukhiqiza, kanye nokusebenza kahle kwesitoreji kungafinyelela63P/h ngomjikelezo ngamunye.

3. Ngaphandle kokwesaba izinselele, ukusungula izinto ezintsha okwenziwe ngokwezifiso

•Eqinisekisa uthuli kanye nokumelana nokushaqeka

•Ukwenza ngokwezifiso okungejwayelekile

•Uidivayisi yenzwa ye-ltrasonic

•TIthwali libekwe engela lama-degree angu-5 emashalofini nasemafolokweni

Inselele 1

Izici zokugcina ama-wafer e-semiconductor yilezi:qinisekisa ukumelana nothuli nokushaqeka, ngaphandle kwalokho kulula ukulimaza ama-wafer abuthakathaka. Ngokusekelwe kulokhu, i-ROBOTECH ithuthukise isakhiwo semishini se-stacker crane sabaukwenza ngokwezifiso okungavamileIsibonelo, kusetshenziswa imisele yomhlabathi ye-aluminium alloy esikhundleni semisele evamile, kusetshenziswa amakholomu e-aluminium alloy adonswa ngokubandayo aqinile kakhulu esikhundleni semisele yensimbi, kusetshenziswa amasondo ambozwe ngerabha esikhundleni samasondo ensimbi, kusetshenziswa ukuphakamisa ibhande lesikhathi esikhundleni sokuphakamisa intambo yensimbi, futhi kufakwa izembozo ezingangeni uthuli epulatifomu yezimpahla.Kusukela esigabeni sokuqala sokuklama imishini, umthelela wothuli nokudlidliza ezimpahleni uncishisiwe, ingozi yokungcola endaweni yokusebenzela engenathuli incishisiwe,futhi isivuno sithuthukisiwe. Izinga lokuhlanzeka lingahlangabezana nezidingo zemvelo zeKlasi 1000.

Inselele 2

Ngenxa yebhokisi lepulasitiki elibonakalayo lesithwali se-wafer, izinzwa ze-photoelectric ezivamile azikwazi ukusetshenziselwa ukuthola impahla. I-ROBOTECH yaklama ngobuhlakani i-idivayisi yenzwa ye-ultrasonicukuthola imithwalo, okungabona ngokuzenzakalelayo isimo sezimpahla emashalofini nasemaphalethini. Futhi ifakwe ikhamera kanye nesikrini sokusebenza ngesandla esiphathwayo ukuze kufezwe ukubonakala okunembile kanye nokulandelela kwazo zonke izinto kuyo yonke inqubo, ngenkathi futhi kuxazulula izinkinga nokuxazulula amaphutha ngendlela elula kakhulu.

Inselele3

Ukuze kuvinjelwe i-wafer ukuthi ingasheleli esithwalweni,isithwali sibekwe engela lama-degree angu-5 emashalofini nasemafolokweni. Ukubekwa okunembe kakhulu kanye nefoloko elizinzile kufezwa ngokufaka isikhala esingezansi sebhokisi le-wafer eziphini ezintathu zokubeka zethuluzi elikhethekile lokufaka ipulatifomu yempahla emoyeni ukuze igcinwe. Ngemva kokuhlola okuphindaphindiwe, ukunemba kokugcina kokubeka kufinyelelwe± 2mm, futhi ukushelela kwefoloko kwafinyelela99.99%Ngaphezu kwalokho, imishini isebenzisa amadivayisi ahlukahlukene okukhiya, okuthuthukisa ngempumelelo ukusebenza kwayo yonke into.ukuzinza kanye nesici sokuphepha.

Njengochwepheshe ezixazululweni zokugcina impahla ezenzakalelayo, i-ROBOTECH yakhe izixazululo zezokuthutha ezihlakaniphilengezinto ze-wafer ezingenakho ukungcola futhi ezingalandelelwa ngesikhathi sangempela, ngokusekelwe emishinini ethuthukisiwe kanye nezinhlelo eziphelele.

Ukuqaliswa ngempumelelo kwale phrojekthi kuphawulaimpumelelo ephumelelayo kwisitoreji ezenzakalelayo se-semiconductor wafer, futhi kusho ukuthiI-ROBOTECH izongena ngokusemthethweni emkhakheni we-semiconductor, ukunika amandla amabhizinisi e-semiconductor ngezixazululo ezihlakaniphile zokwenza izinto ngokuzenzakalela. Esikhathini esizayo, i-ROBOTECH izoqhubeka nokuhlola, iqoqe ulwazi lwemboni, ithuthukise ukusetshenziswa kwezinsiza, futhi ifinyelele ukuthuthukiswa kokusebenza kahle okuphelele.

I-NanJing Inform Storage Equipment (Group) Co.,Ltd

Ucingo oluphathwayo: +86 25 52726370

Ikheli: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Iwebhusayithi:www.informrack.com

I-imeyili:[i-imeyili ivikelwe]

Isikhathi sokuthunyelwe: Ephreli-11-2023